Revision

Hear from us how the works blended with the designs and experience of our engineers turn into works of art in the hands of our talented and experienced teams.

Everything about the 5-cylinder...

In 5 and 2 cylinders, there is a need for planned revision according to the abrasiveness of the product being worked on.

5 roller rolls are cambered and the fineness distribution and winding deteriorate as a result of abrasion depending on the product and time, and as a result, the capacity decreases. Depending on the quality of the cooling water used, the winding deteriorates due to the formation of scale and lime deposits on the inner surface of the rolls. With the revision, the cylinder will reach the initial fineness distribution and capacity values.

We re-modify your cylinders to the latest technology and extend the life of your equipment. We redesign them by equipping them with the latest technology. We turn them into machines that work under the most difficult conditions. You can choose the packages we offer according to your wishes and create the ideal conditions for you.

Roller roller, cambered grinding

We revise your rolls with curved grinding and ensure high quality and increased performance. And with the advantage of on-site service…

Paint Renovation and Stainless Cladding

We make your machines look like the first day with paint and stainless renewal.

Safe Set Grinding

With edge set grinding, we extend the life of your rolls and prevent capacity losses.

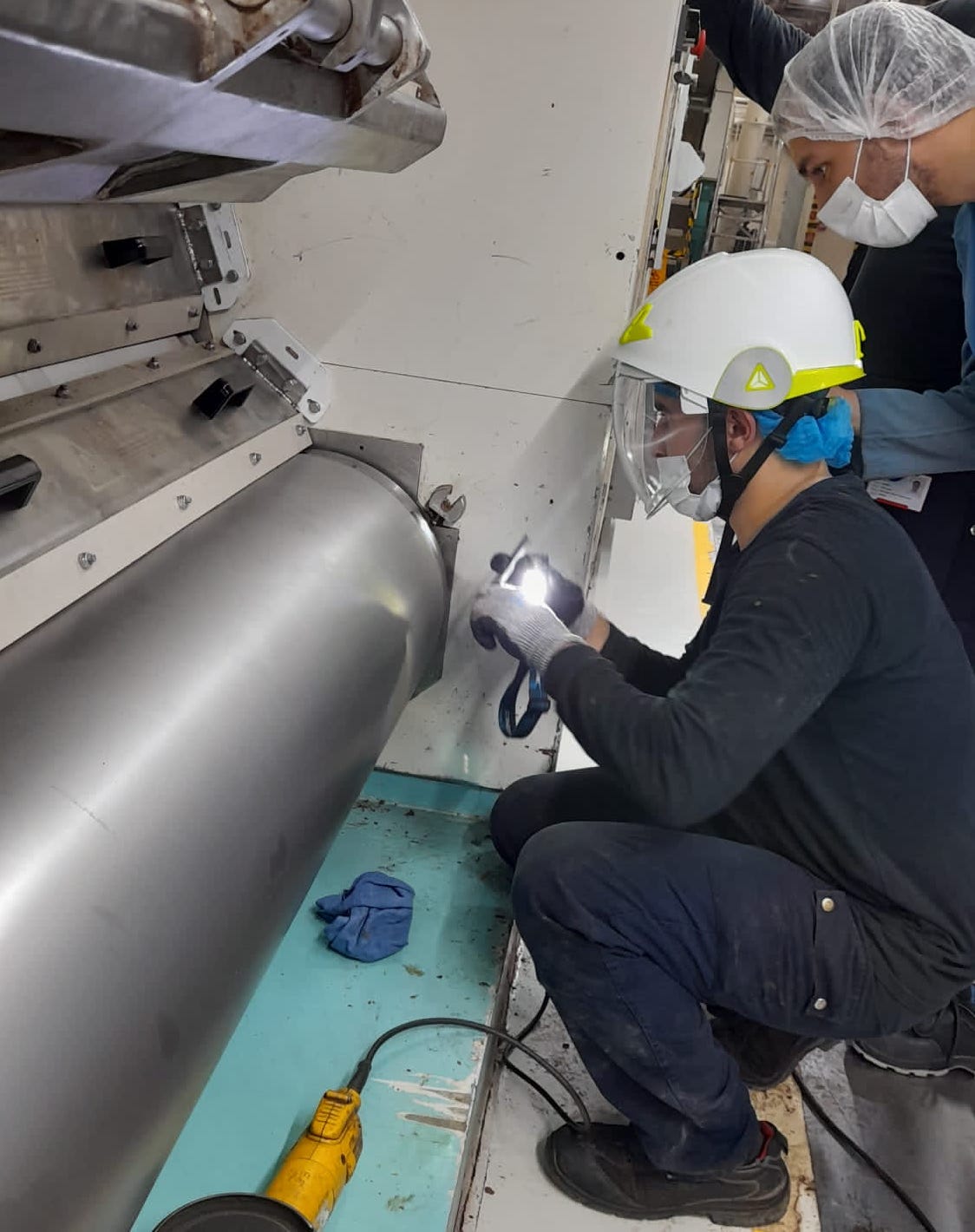

Roller/Top Revisions

We offer ideal quality revision service for your rolls. In order for your machine to return to its first day performance, we provide special curvature values for the product you process. With internal turning, we remove the limestone layers, increase the heat transfer power while keeping the equipment balanced.

We ensure the long life of your wedges with set turning process. We offer you a unique service with our quality of workmanship, equipment and spare parts.

Hear from us how the works blended with the designs and experience of our engineers turn into works of art in the hands of our talented and experienced teams.

In addition to industries such as cocoa, chocolate and confectionery, we also revise your quality machines that you have difficulty trusting anyone. With the universities and research centers we work with, we become your solution center rather than your solution partner.

Birlikte çalıştığımız üniversiteler ve araştırma merkezleri ile çözüm ortağınızdan ziyade çözüm merkeziniz oluyoruz.

Planned Maintenance

We offer solutions that do not disrupt your production plan with annual planned maintenance agreements.

Innovative Approach

With many years of knowledge, know-how and experience, we design for your needs.

On-site Package Solutions

We offer turnkey solutions from A to Z with new line, machine or plant installations.